General Operationsback to top

Belfast, Maine was chosen because of its marine tradition, proximity to the market, and access to clean fresh water and sea water.

No, it is not an experimental facility. Nordic Aquafarms currently operates three commercial facilities and Belfast will be the fourth. Recirculating aquaculture systems, also known as RAS, have been used for decades to farm a large variety of fish, shellfish, marine worms, and plants. Water treatment within the facility will implement the highest level of technology available to ensure optimal fish health as well as a clean water return to the bay. There are dozens of large land-based facilities currently operating internationally, with the highest concentrations in Norway. An increasing number of companies are taking fish to harvest size in these systems as an alternative to net pens, with rapidly developing technology.

Our senior staff has raised salmon for decades. Our designs are modular with independent tank systems. The Belfast facility will be developed in phases which allows for consistency in procedures repeated for each module. Among the companies announcing new land-based facilities, Nordic is one with a unique experience base and the benefit of over 50 employees. Our design team has designed facilities for Grieg Seafood, Marine Harvest, and other large seafood players over the past 20 years. We are fortunate to be a RAS company with this level of in-house experience.

The facility has been permitted to discharge a maximum of 7.7 million gallons per day. Most of the discharged water is water we have borrowed from the bay, and are returning to the bay with less particles than it had coming in. It is rigorously filtered to protect the health of our fish, re-circulated in the tank systems, and treated again before it is returned to the ocean.

A significant portion of this marine water is used for cooling. Passing cool ocean water through a heat exchanger requires less energy than other methods. Fresh water makes up only approx. 15% of this and is a small volume compared to the many other untreated sources of fresh water flowing into the bay today. Most nutrients are removed and recycled before the water is returned to the bay. We remove 99% of total solids, 99% of Phosphorus, 99% of biological oxygen demand (BOD), and 90% of all Nitrogen. These removal rates are the best in the industry.

Some of the most credible environmental institutions in Maine have all written letters of support that are available to the public, stating that they do not see any material impact on the bay from our residual discharge. These institutions include the Atlantic Salmon Federation, The Conservation Law Foundation, and the Gulf of Maine Research Institute. They did an independent peer review of our discharge application, drawing from strong scientific and ecological know-how.

It’s in our own best interest to monitor all discharge, in addition to any monitoring requirements put forth by the DEP. We want and need clean water and support overall protection efforts in the bay. Our brand is built on an environmental platform, and the health of this ecosystem is of great importance.

The discharge pipe will extend approximately 1 kilometer from shore. Environmental scientists worked to find an optimal placement based on extensive studies of the bay, currents, and modeling. The placement is based on optimal dispersion point at a preferable depth and the pipe will not be visible as it will be buried below the intertidal.

We are approved for permits that allow for long-term growth of this business in Belfast. The first phase of development will be less than 50% of the planned facility in terms of production capacity. The nutrient discharge in phase 1 will also be under 50% of the permit application level. We will share information on a dedicated web page for the community to follow our development over time. By securing permits that allow for long-term development, we are also securing the opportunity to add jobs and development in the community for many years to come.

While lights are used inside the facility at night to create a stable environment for our fish, the facility does not include windows or skylights that allow light to escape at night. Walking paths will be lit with downward facing lights for employee safety. Most entrances and walking paths are in between buildings.

No. All processes take place indoors. Fish tanks are clean and emit no odors. Co-products are stored indoors in sealed containers to prevent odors and frequently removed from the facility.

Fish Related Questionsback to top

Our facilities are escape-proof. The Belfast facility will be a minimum 300 feet from any open water source. Multiple mechanical barriers are in place to prevent escape in pipes. For example, our final ultra-filtration step on the discharge treatment is 0.04 micron – small enough to remove bacteria.

No, Nordic does not have any plans to use GMO fish. Based on practices and knowledge of consumers in our market at least, our decision is we will not pursue that. Genetically engineered fish are not part of the plan.

The nutritional requirements of the fish can be met with a broad range of ingredients that are derived from crops, agricultural byproduct, and sustainable fisheries. More innovative break-through ingredients include fermented single cell proteins, insect meals, and algae oils.

Currently, feed contains approximately 15-20% marine ingredients, where 35% of that are primarily sourced from fisheries processing by-product such as heads and trimmings. The rest comes from sustainably managed fisheries.

Feed manufacturing for aquaculture is an innovative, and sustainable-minded industry. Nordic will be working closely with the feed producers to refine our formulations that prioritize the inclusion of non-marine derived protein sources.

Nordic Aquafarms, Inc. operates on the basis that fish health and welfare is directly related to quality of our feed, our water, our husbandry practices, and our farm management. We minimize the risks to fish health and welfare by creating the highest standards in fish health management and farm biosecurity. The NAF Fish Health, Welfare, and Farm Biosecurity Management Plan is a fish health program that is evidence-based, tailored to our facilities, and establishes responsible and professional veterinarian health management. It is the diligence of NAF’s fish health team and a strong program that will minimizes disease risk to the farm and environment through proper quarantine, robust biosecurity, daily fish health assessments, proven health diagnostics, and staff education.

Yes, vaccination will be one of the many tools Nordic will employ to ensure their fish are always healthy and well cared for. Fish welfare is of paramount importance to Nordic. NAF will favor the use of preventative health tools over prescription medicines, and vaccination is one such way to protect fish against severe disease outbreak from endemic pathogens. Vaccines are biologic substances that are required to provide fish with immunity against specific diseases. Vaccination can also protect the farm against pathogen amplification by reducing the shed of pathogens and raising the threshold of pathogen load required for infection. Vaccines used for protection against high-risk endemic pathogens are prescribed by the farm veterinarian through a legal VCPR relationship (Vet-Client-Patient-Relationship).

Environmental Concernsback to top

Nordic is a farm growing fresh food for customers in the Northeast. We rely on clean water and a healthy environment to grow our fish. The businesses of the future must incorporate both social responsibility and financial objectives to be truly successful in the long-term. Our brand and future certifications are highly sensitive to our environmental stewardship practices.

Investment in environmental technologies demonstrates our dedication to protecting the environment, and why Nordic Aquafarms is supported by serious environmental organizations. Our production requires clean water to produce high quality fish. We have every incentive to be an environmental steward in Belfast to ensure clean water in the future.

Nordic uses Recirculating Aquaculture Systems (RAS) in an indoor, biosecure facility.

For example:

- Nordic cleans and reuses production water.

- Nordic treats all water coming in and out of the farm for disease-causing pathogens.

- Nordic removes all solid waste from effluent and only discharges treated water.

- Nordic has extensive barriers to prevent fish escape.

- Nordic does not need medication and pesticides to treat parasites such as sea lice as they cannot enter the farm due to our extensive filtration and water treatment before the water enters the farm.

No. Our buildings will displace approx. 30 acres of forest that had been logged on a regular basis by its previous owners. We are also replanting areas and maintaining green visual buffers. In addition, we have worked with the city to protect the Little River trails and waterfront for the community to enjoy through a donation.

We do not use growth hormones, antibiotics, or pesticides in our daily production. We produce a natural product and thus do not add any harmful chemicals to the production water.

FDA approved cleaners and disinfectants are used to clean other parts of the facility and are not directly discharged in any material quantities.

No. Biosecurity and fish welfare are the primary considerations for the farm design and operation. In addition to the biosecurity measures in place to ensure that the facility remains disease free, all water leaving the fish production areas including floor drains and processing will undergo extensive treatment of ultrafiltration through 0.04-micron filters equivalent to 1.5748e-6 inches in size before passing through UV disinfection at 300mJ/cm2. Fish health is closely monitored on the farm to manage and contain any early onset of disease if it were to occur.

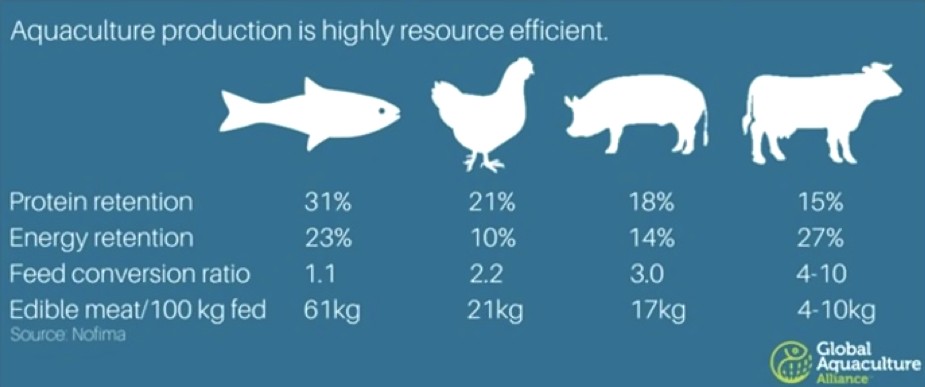

On the global scale, the US ranks #1 in chicken and beef production, and #2 in pork production. However, we rank #16 in seafood production. We have much work to do. Salmon have a higher percentage of protein and energy retention when compared to the other protein sources on the graphic below. The feed conversion ratio is also the most efficient, given that for every 1.1 pounds of feed, you get 1 pound of fish.

When we look at the efficiency in use of local resources, our salmon will be one of the most resource efficient.

Currently, over 90% of fresh salmon is airfreighted into the US, and half of all fresh seafood is thrown away. The Belfast facility will displace a portion of imports from overseas locations with a local craft seafood product. At Nordic, we plan to distribute our salmon by truck, as airfreighting produces much more CO2 than our local strategy.

We’ll be able to get our fish to consumers faster than imports, giving people more available days for their fish to be fresh. Reducing food waste is the most effective way of reducing CO2.

We further reduce our footprint by employing renewable energy solutions.

No. Our wastewater system removes 99% of phosphorous, total suspended solids, and biochemical oxygen demand, and 90% of the nitrogen in the effluent. The residual discharge is going into a bay containing trillions of gallons of water- like a drop of water in a bucket. Even though we go far beyond current industry standards by removing 90% nitrogen, we do have elevated levels of nitrogen compared to background levels. The residual discharge is, however, less than 1% of the nitrogen already going into the bay. If other current dischargers raised their treatment level to only 50 % of our level, we would see material reductions in nutrient discharge along the entire coastline.

The Gulf of Maine Research Institute and the Conservation Law Foundation have reviewed our application and not found cause for concern. We will remain diligent in contributing to the health of the bay as a part of our environmental stewardship strategy.

No. Extensive pump testing and modeling confirmed this and the groundwater levels at our facility and the surrounding neighborhood will be under continuous monitoring. Nordic has further agreed to make whole any homeowner who has issues with their well. The overwhelming majority of homes and businesses are served by municipal water, with only a handful of homes still employing wells. We rely on freshwater for our fish and have three different available sources. The site we chose is unique in that the impoundment of the Little River previously supplied the drinking water for the city of Belfast and Northport for close to a century. We have been permitted the use of multiple ground water wells, withdrawal of water from the reservoir, and can use municipal water supplied by the Belfast water district. This allows us sufficient flexibility to balance which water supply we use.

Lastly, the facility will employ seawater for most of its processes.

The extensive data collection and secondary assessments done by an additional environmental consultancy conclude that our proposed withdrawal will not have negative effects on the overall health of the watershed area in Belfast. It also concludes that other local wells are safe. We will have fully transparent monitoring practices in place to give assurances to the community in the future.

Economic Impact and Employmentback to top

Nordic will prioritize and optimize opportunities for local contractors. Nordic is using Gilbane for construction management and general contractor. Nordic and Gilbane will work to create smaller bid-packages and sub-contracts. The Nordic project is expected to create approximately 250-300 jobs annually during the multi-year construction period.

Nordic expects to offer about 150 full-time jobs with benefits when the facility is fully built out. In addition, there will be many indirect jobs generated in support of the facility (truck drivers, food service, etc.)

The project will create many ancillary business opportunities for local entrepreneurs. Nordic is committed to working within a circular economic model wherever feasible. The more local the solution, the better the fit it will likely be for our operations, service, and support.

Wages, ancillary spending will result in millions of additional dollars infused into the local economy and local spending on supplies and services will increase during Nordic’s multi-year construction phase.

We’ve had opportunities to work with all grade levels with in-classroom and virtual interactive presentations. Nordic is excited to work with the newly launched Marine Institute at Belfast Area High School to introduce information to students about careers in aquaculture, support in-classroom educational programs and more. Nordic staff have been instrumental in connecting with Maine’s colleges and university programs in assisting with the development of RAS-oriented curriculum and career paths. Additionally, to facilitate movement within the company, NAF will be creating on-site career development opportunities for employees.

Community Engagementback to top

Our team has gone to great lengths to be transparent, inclusive, and comprehensive in our research and sharing results throughout the public process. Nordic conducted multiple public information meetings, met with interested stakeholder groups and residents, and held numerous presentations for local groups.

Our Public Relations and Outreach Manager, Jacki Cassida, is available to help communicate with and educate the public about the project. Jacki can be reached at jacki.cassida@nordicaquafarms.com.