Yellowtail Kingfishback to top

We will not be raising Atlantic salmon in California. We will be focusing on Yellowtail kingfish

Yes. As described above yellowtail kingfish require ~10% less energy to produce than Atlantic salmon grown in the same recirculating systems. As a marine species, Yellowtail kingfish do not require freshwater to grow. As in Denmark we will include brood stock at our farm. This will allow us to produce our own eggs and fingerlings. Therefore, we will not need to import our eggs from another farm, ensuring increased biosecurity on our farm.

No. This does not change the nature of the farm or what we will do; grow premium, fresh fish for the regional market.

No. All of the robust escape and biosecurity measures previously described for Atlantic salmon will still be in place. The farm will be smaller and therefore discharge and waste removal will be reduced.

No. We will use less energy. We have nearly identical grow out modules in Denmark and Norway called RAS 2020s. In Fredrikstad, Norway we have been growing Atlantic salmon in RAS 2020 modules and in Hanstholm Denmark we have been growing Yellowtail kingfish in the same RAS 2020 design module.

Due to our ability to capture and use waste heat we have demonstrated at a commercial scale that roughly 10% less energy is required to grow Yellowtail kingfish vs Atlantic salmon, and heat exchangers use less energy than chillers.

No. The discharge temperature will be cooler than what it would have been for Atlantic salmon. We will use heat exchangers to remove the heat from the effluent before it is discharged. This will result in effluent that will be similar to the temperature of the receiving waters of the Pacific Ocean 1.55 miles out in ~80 feet of water at our outlet diffuser array.

No. The project remains the same. We will clean up a brownfield to build a land-based fish farm. We will operate within the bounds of what we have already described and analyzed. This includes effluent, energy use, GHG, and traffic.

No, this will not affect the findings in the EIR. The proposed change in species will result in less or the same level of impacts analyzed in the EIR. The references to yellowtail kingfish are based on a 1:1 comparison and not the current plan for a ~2,000-3000 MT facility.

The general plan for building out the facility in phases over time remains the same. However, the project will start smaller than what it would have been for a first phase with Atlantic salmon.

Yellowtail kingfish are pelagic schooling fish found throughout the Pacific Ocean. Yellowtail can grow up to 2m and are common to 1m in fork length. Yellowtail kingfish are often seen schooling as adults and are often found near rocky reefs and sandy areas in coastal waters and may enter estuaries.

Young fish up to 7kg are known to form shoals of several hundred fish. They are generally found close to the coast, while larger fish are more common around deep reefs and offshore islands and can reach upwards of 70kg.

They are native to California but concentrated in Southern California where waters are warmer. They rarely travel to Northern California and only during warm years.

This was a strategic decision by Nordic Aquafarms Europe, where yellowtail kingfish has been successfully farmed by our Denmark facility since 2016.

General Operationsback to top

Everything from eggs produced by our own brood stock to harvest happens indoors in a closed life cycle- importing eggs will be unnecessary. The priority is to maintain excellent fish health and welfare, good nutrition, and good water quality. Their quality of life is important, and part of every decision made on the farm.

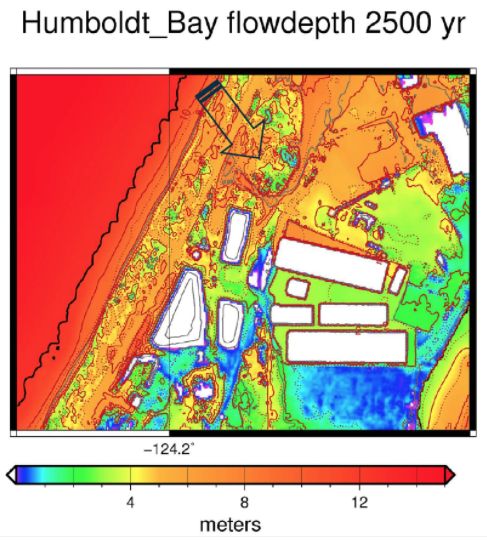

No. Nordic engaged renowned Tsunami expert Dr. Gary Chock to assess the site and make recommendations on how to build a safe, structurally sound and escape proof facility. Study results confirm that a 2,500 year tsunami event will not overtop or breach our fish tanks or result in the escape of any fish from the facility.

Nordic will be raising all fish inside buildings in closed tanks on land. Nordic uses recirculating aquaculture systems (RAS) that treats water from the fish tanks so it can be reused within the tank. Nordic raises the fish in sea water in its grow-out tanks. This dramatically reduces the amount of freshwater required to produce salmon at the facility.

RAS features:

- All production takes place indoors.

- Water is recirculated and continuously treated to maintain good water quality for the fish.

- Water exchange is maintained through intake and discharge of moderate volumes of water per pound of fish.

- Feeding, light, water quality, and temperature are constantly monitored and optimized.

- Production staff have close contact with fish to monitor health and welfare.

- Back-up systems ensure reliable operations.

While lights are used inside the facility to create a stable environment for our fish, the facility does not include windows or skylights that allow light to escape at night. Walking paths will be lit with downward facing lights for employee safety. Most entrances and walking paths are in between buildings.

Humboldt County is uniquely positioned with infrastructure necessary to support RAS and other aquaculture facilities – presenting an opportunity to grow this important industry cluster on the West Coast.

The North Coast offers:

- Clean, abundant fresh and sea water

- An existing industrial water line that can deliver fresh water from the Mad River directly to the project site

- Existing sea water intakes (sea chests) that can be utilized to deliver sea water to the Nordic facility

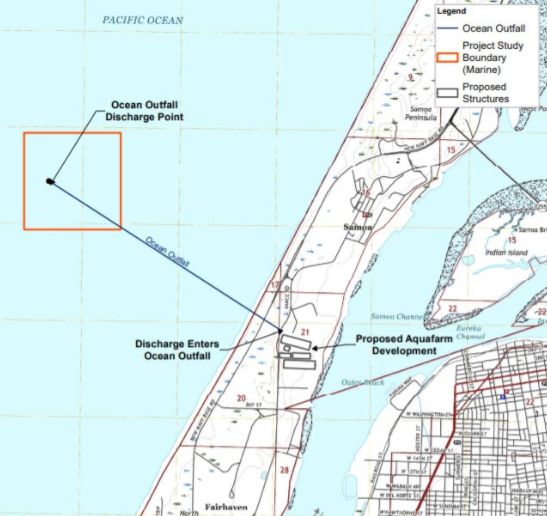

- An existing outflow pipe that can be utilized to discharge filtered, disinfected effluent water into the ocean 1.5 miles off shore

- The community has a strong fisheries heritage, academic institutions and interest in environmentally responsible emerging technologies and innovation.

- California has a good reputation of quality, sustainability and food safety.

No. Fish tanks are clean and omit no odors. Waste products are stored indoors in sealed containers to prevent odors.

Nordic will encourage carpooling, cycling and bus transportation, and will seek to incorporate electric vehicle charging stations on-site and more to reduce traffic impacts. Shift work at the facility will allow for a stable bus route off and onto the peninsula increasing opportunities for the general public to utilize bus service to the peninsula.

Nordic operations will require less than 15 truck trips per day, which is less than 5% percent of current traffic and is not anticipated to impact the peninsula’s residents or recreational visitors.

Fish Related Questionsback to top

- Nordic early plans are to produce ~2-3,000 metric tons of fish annually with potential for incremental expansion.

- Fish will be processed onsite into consumer ready products.

- Fresh (not frozen) fish will be distributed to west coast markets.

In addition to all the biosecurity measures in place to ensure that the facility remains disease free, all water leaving the fish production areas including floor drains and processing will undergo extensive treatment of ultrafiltration through 0.04 micron filters equivalent to 1.5748e-6 inches in size before passing through UV disinfection at 300mJ/cm2.

Nordic uses immunization through a vaccination program combined with veterinary monitoring and testing to ensure our fish are healthy without the need for employing antibiotics or medications.

Eggs are sourced from pathogen free broodstock, disinfected prior to entering the farm, and placed under quarantine until they pass a certified health inspection. Every cohort of fish is tested for all pathogens of concern before being released from quarantine.

Incoming water is filtered to such an extent that bacteria, pathogens, parasites, and viruses are removed; water is further sterilized using ultraviolet light before contact with fish.

An accredited veterinarian will work with us to conduct fish health checks in the facility on a regular basis. Staff will be trained to understand fish behavior and appearance to identify early signs of health issues.

Bio-security measures prevent movement of pathogens onto the farm via people, feed, equipment, pests, or other vectors.

The facility is designed to be escape-proof.

- All fish are raised inside secure buildings

- Fish are never outside. They are moved through dedicated underground pipes preventing their escape as they move from one building to another

- The facility has numerous physical barriers specifically employed to prevent fish escapement

- The wastewater treatment facility is impassible by fish.

- All pipes for moving fish are contained on the farm and none terminate at the ocean or bay.

- Even a 2,500 Tsunami event will not over-top tanks

- Security measures to include 24/7 on site staffing, video surveillance, and key card access doors, prevent any manual (human) removal of fish from the facility

The nutritional requirements of the fish can be met with a broad range of ingredients that are derived from crops, agricultural byproduct, and sustainable fisheries. More innovative break-through ingredients include fermented single cell proteins, insect meals, and algae oils.

Feed manufacturing for aquaculture is an innovative, and sustainable-minded industry. Nordic will be working closely with the feed producers to refine our formulations that prioritize the inclusion of non-marine derived protein sources.

Nordic will be utilizing the best technology available to make feed utilization as efficient as possible, with automatic feeders, AI, better recirculating systems, and always improving nutritional knowledge.

Environmental Concernsback to top

No. The Humboldt Bay Municipal Water District has carefully studied the water supply. Approximately 2 million gallons of fresh water will be diverted from the Mad River using existing industrial infrastructure. This is approximately 6-7% of the previous water volume supplied to the pulp mills through the industrial water line when they were operational.

Freshwater will only be needed for processing and for employee use. Atlantic salmon require freshwater in the early portions of their lifecycle, where yellowtail kingfish do not. Yellowtail kingfish are a marine fish.

In addition to completing the EIR (Environmental Impact Report) under the CEQA (California Environmental Quality Act) process, Nordic will obtain several permits in order to build the facility in Humboldt.

The main permits are:

- Coastal Development Permit (CDP) from Humboldt County for development of the site within the Humboldt Bay Area Plan, Local Coastal Plan (LDP) jurisdiction

- Coastal Development Permit (CDP) from the California Coastal Commission for the discharge to comply with the Coastal Act

- National Pollutant Discharge Elimination System (NPDES) permit including compliance with the Water Code Section 13142.5(b) for water intake from Humboldt Bay

- Air quality permit from the North Coast Unified Air Quality Management

The Harbor District will also obtain permits for water intake from the Sea Chest from the California Coastal Commission.

The Harbor District worked with the EPA to conduct initial site clean-up of most hazardous substances, including several million gallons of black liquors used in producing pulp.

Other debris had been left on site and now includes scrap metal, decaying buildings covered with lead, asbestos and other public hazards such as open pits and buildings with material falling off of them, and areas of contaminated soil.

Nordic will be responsible for the remaining clean-up of industrial debris and demolish abandoned buildings, addressing lead, asbestos and other hazardous materials remaining on-site. Nordic will also remove any potential contamination ensuring clean-up of the site and create a new, environmentally sustainable stormwater system that treats all the stormwater.

No. Nordic’s high-level filtering and disinfection means that discharge is essentially filtered water with traces of nutrients. More than 99% of phosphorus, biological oxygen demand (BOD) and total suspended solids (TSS) are removed before the effluent is discharged into the ocean. High discharge treatment ensures that there is no significant impact to the surrounding waters or marine life at the point of discharge.

RAS aquaculture has been endorsed by multiple agencies, including the Monterey Bay Aquarium, The Atlantic Salmon Federation (wild salmon conservation), Nature Conservancy, Food and Water Watch, Global Aquaculture Alliance, Sierra Club, Wild Fish Conservancy and more.

Nordic uses Recirculating Aquaculture Systems (RAS) instead of net pens, flow-through raceways or ponds. Land-based RAS farming was developed to mitigate impacts of these other types of fish farming.

For example:

- Nordic cleans and reuses our production water. Others don’t.

- Nordic treats all water coming in and out of the farm for disease-causing pathogens.

- Nordic removes all solid waste from effluent and only discharges treated water.

- Nordic has extensive barriers to prevent fish escape.

- Nordic does not need medication and pesticides to treat parasites such as sea lice as they cannot enter the farm due to our extensive filtration and water treatment before the water enters the farm.

Economic Impact and Employmentback to top

Nordic is using Gilbane for construction management and general contractor. However, Nordic will prioritize and optimize opportunities for local contractors by creating smaller bid-packages and sub-contracts.

The Nordic project is expected to create approximately 250-300 jobs annually during the multi-year construction period.

Nordic is producing Yellowtail Kingfish (seriola lalandi), which is not a species that are commercially fished in Northern California.

Nordic wants to replace farmed yellowtail kingfish currently imported via airfreight from Japan and Australia 9,000 to 13,000 miles to reach the shelves on the west coast with a fresh, locally grown product.

Nordic plans to hire as much qualified workforce as possible from the local area.

Nordic expects to offer about 100 full-time jobs with benefits in Phase 1, and up to 150 when the facility in fully built out. In addition, there will be many indirect jobs generated in support of the facility (truck drivers, food service, etc.)

Nordic expects approximately 250-300 construction jobs during the demolition and construction period.

Nordic is working closely with College of the Redwoods to revitalize their aquaculture program and with Cal Poly Humboldt to ensure a steady pipeline of LOCAL qualified professionals. Nordic is also working with the Humboldt County Office of Education to introduce information to students about careers in aquaculture, support in-classroom educational programs and more.

Business Development – The project will create many ancillary business opportunities for local entrepreneurs.

Property Tax increases – Site improvements, a subsequent increase in property value and property tax will increase county revenue. Estimated tax revenue will be based on the valuation of the facility through an appraisal process.

Increased local spending – Wages, ancillary spending will result in millions of additional dollars infused into the local economy and local spending on supplies and services will increase during Nordic’s multi-year construction phase. The consulting company Implan estimated for Humboldt County that the impact of direct, indirect and induced labor impact (value stemming from the spending of labor income) would be approximately $48 million annually.

Catalyst for additional development and improvement – The County has established an Enhanced Infrastructure Financing District (EIFD), which will support additional infrastructure enhancement on the peninsula, further increasing business development opportunities.

Community Engagementback to top

Nordic has engaged in informal communication w/ tribal representatives since March 2019.

Archaeologist James Roscoe of Roscoe and Associates worked closely with Tribal Historic Preservation Officers (THPOs) to complete a thorough Culture Resources Report. The final report is confidential and is not disseminated to the public.

Nordic has conducted regular outreach with tribal leadership and membership during the permitting process and continues to communicate with them to keep them updated on the process.

Nordic has offered to engage a cultural resources monitor when appropriate during project construction.

The Nordic team has gone to great lengths to be transparent, inclusive and comprehensive in their research and sharing results throughout the public process. Nordic has a Public Relations and Outreach Manager, Jacki Cassida, available to help communicate with and educate the public about the project. Jacki can be reach at jacki.cassida@nordicaquafarms.com.

Nordic has shared study findings with Baykeeper, EPIC, NCEC, The Salmonid Restoration Federation, Humboldt Fishermen’s Marketing Association and more as requested.

Nordic has conducted multiple public information meetings, been meeting with all interested stakeholder groups and local residents and held numerous presentations for local groups. In addition, Nordic has held in-person/digital office hours every week to answer questions from local residents.

EIR Applicationback to top